How to adjust the wheel hub bearing of forklift and replace the lubricating oil of wheel hub bearing?

1. Adjustment of wheel hub bearing

The adjustment method and technical requirements of the front and rear wheel hub bearings of forklift are the same, taking the front wheel as an example.

1. Install the front wheel hub back on the steering knuckle shaft, put on the outer bearing and screw on the high-speed nut, then turn the wheel while tightening the adjustment nut with the wheel hub wrench until it is tight enough to stop the wheel immediately after letting go, and then return the adjustment nut 1/8-1/5 turn to make it rotate freely without axial clearance.

2. After adjustment, install the locking washer and lock plate back, tighten the fixing nut, and lock it with the lock plate, and then install the bearing cover or half-axle flange back.

3. After adjusting the wheel hub bearing, when checking during driving operation, the wheel hub should not feel hot when touched by hand.

2. Replacement of wheel hub bearing lubricant

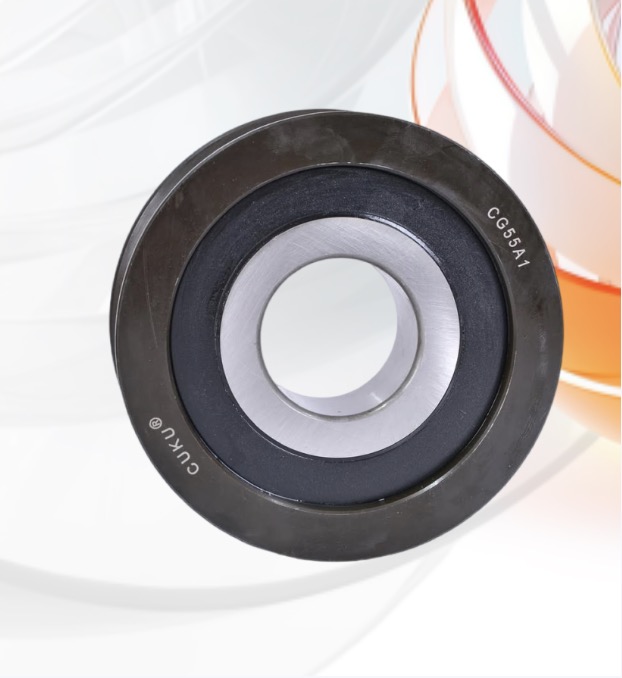

1. Remove the wheel and wheel hub, take out the oil seal and inner bearing, scrape off the grease on the wheel hub and journal, and wipe it clean with an oil cloth; thoroughly clean the tapered roller bearing and blow it clean with compressed air.

2. Fill the tapered roller bearing with grease, apply a layer of grease inside the wheel hub to prevent rust, and reinstall the inner bearing and oil seal.

3. After lubrication, reassemble the wheel hub in the opposite order of disassembly and adjust it, and install the wheel. Since the thread direction of the tire bolts is opposite (left is reversed and right is correct), the left and right wheel hubs cannot be installed incorrectly.